Background and Context

Can you provide an overview of the series of aged care facilities we have provided this solution?

We have completed about 30 systems from Auckland to Christchurch

What prompted the need for a new hot water production solution?

The client is driven by two main needs, the replacement of plants at the end of life and the desire to reduce operational carbon. Typically, as the existing plant ages and needs to be replaced the client will then look at the option of either replacing like for like or moving to a more renewable solution. Some clients are more strongly motivated by carbon management and will replace the existing plan which is not at the end of life.

How was hot water production managed before implementing this solution?

In this application, the hot water was gas instantaneous coupled to storage vessels, very typical for light commercial DHW in New Zealand.

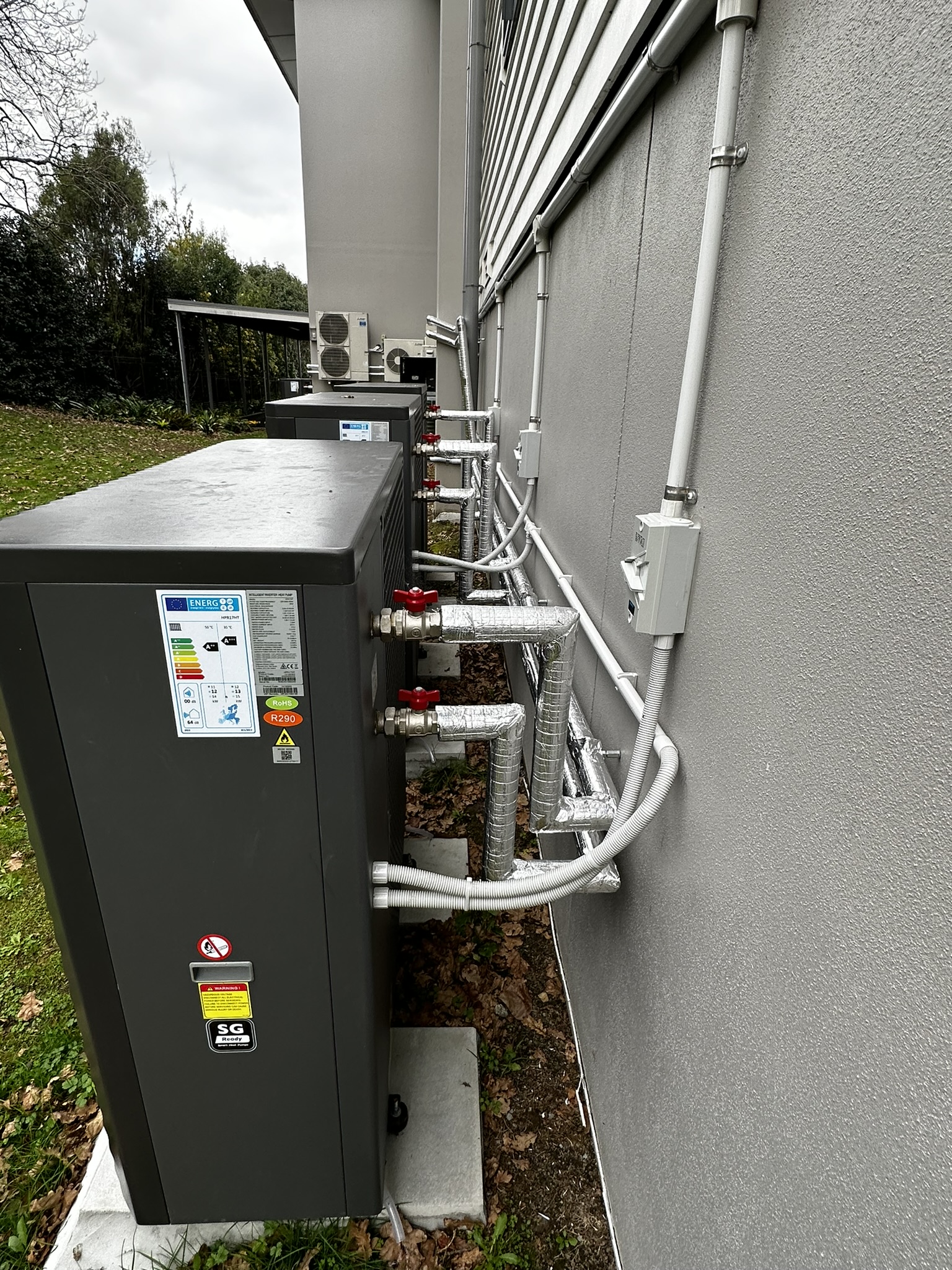

What specific features does the hot water production system offer?

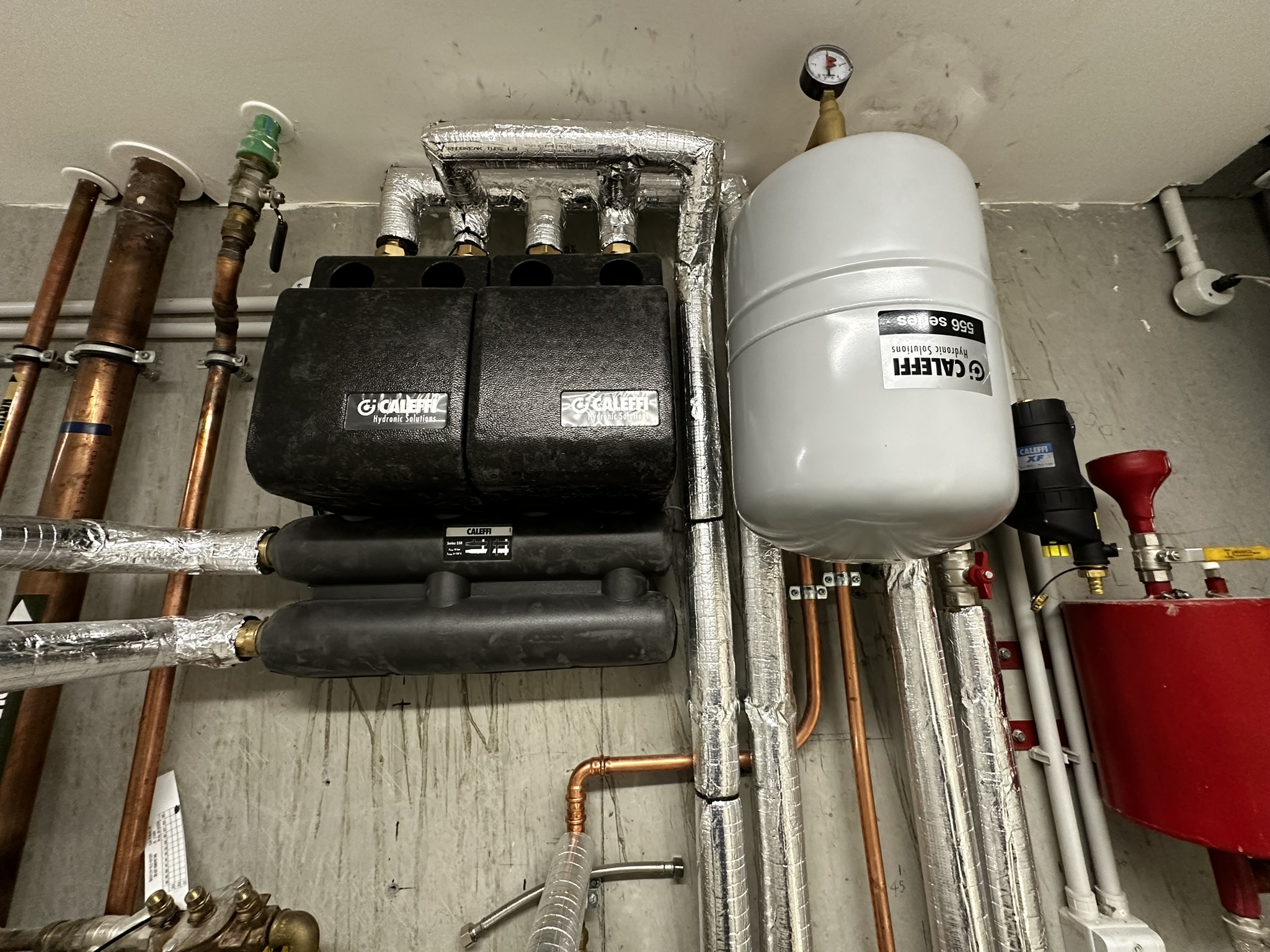

Primarily the most critical component is the R290 high-temperature heat pump. The multi-pass action of the appliance allows us to have a wide modulation range which works well under draw-off, recovery, and maintenance, all three phases of operation are managed by the heat pump only with no electrical boosting and we can achieve a storage temperature of 65ºC which is critical for age care applications.

Implementation Process

Were there any challenges faced during the implementation process? How were they addressed?

One of the biggest challenges for these types of re-powerment projects is having enough amps to drive the selected appliances. With careful specification, it is possible to adjust the recovery power and storage capacity to meet the hot water requirement from stored capacity and then recover the tanks over a longer period than we would typically do with gas. This helps keep the amp requirement down to more manageable levels.

How did you ensure a smooth transition from the old system to the new one?

Most of these projects require the hot water production to be off for as short a time as possible. The cylinders we provide have electrical backup built in, this allows us to run on element power temporarily while we finish the heat pump installation.

Pureflow Software

What is Pureflow?

Pureflow is an in-house engineering tool we have developed to assist in rapid specification and performance molding for renewable DHW systems.

How does Pureflow simplify the design and planning of the hot water production system?

Pureflow automatically creates the equipment schedule, estimates the cost, and models the systems’ running cost and operational carbon vs electric element and gas-based systems.

What features of the Pureflow are most beneficial for the customer?

The reduction in engineering hours to produce the high-level design of the system with all the import metrics for decision-makers to make informed decisions is of excellent value to the market. Currently, a system must be scoped and designed by a hydraulic consultant, a performance model must be built, and the job must go out to tender, typically with multiple suppliers and installation trades all providing information to produce the case for evaluation. Pureflow performs those steps automatically with a compressed timeline and cost. Once the client has enough information to make an informed decision, the engineer can move into detailed design with a realistic budget and scope set out.

How does the software assist in ensuring compliance with industry standards and regulations?

The modeling the system provides gives a clear expected performance to meet the client’s requirements.

Performance and Outcomes

What improvements have you observed in the specification process since implementing Pureflow?

The ability to provide a realistic cost and power requirement of the system without investing a high amount of engineering hours greatly.

How has the quality and reliability of the hot water production system changed?

Having a clearer expectation of system performance which dynamically updates during the specification helps tune the design parameters to achieve the level of performance required to meet the duty.

Can you share any data or metrics that highlight the performance improvements resulting from the software?

The ability to turn around designs quickly with a high level of documentation has given the market confidence in our technical ability and experience in this specialist heat pump application.

Have there been any unexpected benefits from using Pureflow?

Having a collaborative approach with the consulting engineering community has allowed us to create more value as a supplier and deepen our relationships with engineers who regularly operate in this space.

Cost and ROI (Return on Investment)

Have there been any ongoing costs or savings associated with the specification software?

It has reduced the amount wasted engineering time a great deal, now a system can be scoped and estimated with a small amount of effort and clients who do not have the budget for these types of systems can make the decision not to proceed before consuming a lot of time and effort.

Click here to read about other projects for re-powerment and hot water production.

Feedback

What has the general feedback been from the customer?

The feedback is excellent, and the ability to produce the drawings and performance model dynamically is eye-opening when working with clients live.

Has there been any feedback from the consulting engineers who have experienced the assistance that Pureflow provides?

The level of expertise and support we can offer to the consulting engineers has been well received.

Written by Darren Yearsley